Services

Services

What Service We Provide

CNC Machining

Our CNC machining services offer precision manufacturing for complex components with tight tolerances. Utilizing state-of-the-art CNC machinery, we provide high-volume production capabilities as well as custom parts tailored to your specifications.

Key Features:

- Advanced CNC technology for accuracy

- Capable of machining various materials (metals, plastics, etc.)

- Suitable for prototyping and production runs

Applications:

Automotive parts, aerospace components, medical devices, and more.

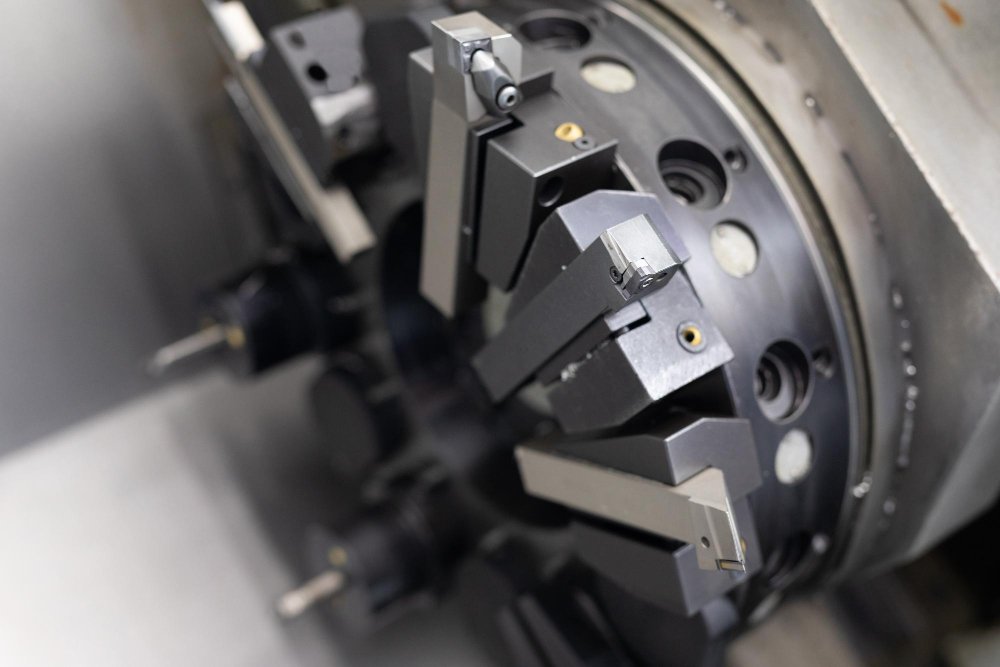

Turning Services

Our turning services involve the precise rotation of materials to create cylindrical components. We utilize advanced lathes to produce high-quality turned parts, ensuring precision and consistency for all your manufacturing needs.

Key Features:

- Expert turning of diverse materials

- Customizable diameters and lengths

- Capable of both small and large production runs

Applications:

Shafts, bushings, pulleys, and other cylindrical parts.

Milling Services

We offer comprehensive milling services, employing vertical and horizontal milling machines to produce intricate shapes and features. Our skilled technicians ensure precise dimensions and superior surface finishes on all machined parts.

Key Features:

- Versatile milling capabilities for complex designs

- High precision and repeatability

- Customizable to fit project specifications

Applications:

Brackets, plates, and other intricate components.

Grinding Services

Our grinding services provide exceptional surface finish and tight tolerances on a variety of materials. Using advanced grinding techniques, we can enhance the dimensional accuracy and surface quality of your components.

Key Features:

- Precision surface grinding and cylindrical grinding

- Suitable for high-volume and custom projects

- Capability to grind a range of materials

Applications:

Gears, spindles, and other precision components.

Fabrication Services

In addition to machining, we offer complete fabrication services to support your project needs. Our team can handle everything from cutting and bending to welding and assembly, providing you with a comprehensive solution.

Key Features:

- Full-service fabrication capabilities

- Custom designs to meet project specifications

- Quality assurance at every stage of production

Applications:

Custom machinery, frames, and industrial structures.

Prototyping Services

We provide rapid prototyping services to help you test and validate your designs before full-scale production. Our team works closely with you to refine your concepts and ensure they meet your expectations.

Key Features:

- Fast turnaround times for prototypes

- Collaboration to optimize designs

- Cost-effective solutions for early-stage projects

Applications:

Product development, design validation, and concept testing.

Customized Machining Solutions for Every Industry

At Asha Engineering Solutions, our commitment to quality and precision drives every project we undertake. Whether you need CNC machining, turning, milling, grinding, fabrication, or prototyping services, we have the expertise and technology to deliver exceptional results.

Our Capabilities

Our Amenities & How It Looks Like

State-of-the-Art Facilities to Drive Precision and Excellence

At Asha Engineering Solutions, we pride ourselves on offering a cutting-edge environment designed to meet the demands of modern manufacturing. From advanced machinery to dedicated customer service, our facilities are equipped with everything needed to deliver superior machining solutions.

On-Time Delivery Rate

We take pride in our consistent track record of delivering projects on time, ensuring your operations never face unnecessary delays. With our efficient workflow and dedicated team, we strive to exceed your expectations with every order.

Precision and Accuracy

Our commitment to precision machining ensures that each component is manufactured to exact specifications. Utilizing advanced CNC technology and a rigorous quality control process, we maintain a 99% accuracy rate in every project.

Customer Satisfaction Focus

0

%

At Asha Engineering Solutions, our clients are our top priority. We go the extra mile to understand your unique needs and provide tailored solutions. Our hands-on approach and personalized service ensure your complete satisfaction from start to finish.

1. Advanced Machinery & Technology

Our workshop is equipped with the latest CNC machines, lathes, milling machines, and grinders. This state-of-the-art equipment allows us to deliver high-precision results, whether for large production runs or custom jobs.

Key Features:

- Multiple CNC machines for increased production capacity

- Advanced lathe and milling systems for intricate designs

- Precision grinding equipment for tight tolerances and superior finishes

2. Skilled Workforce

Description:

Our team consists of highly trained engineers, machinists, and technicians who bring years of experience and expertise to every project. Continuous training ensures they stay updated with the latest industry practices and technological advancements.

Key Features:

- Expert team with a focus on precision and quality

- Continuous learning and development programs

- Dedicated to on-time delivery and customer satisfaction

3. Quality Control & Inspection

Description:

We have a stringent quality control process in place to ensure every product meets the highest standards of accuracy and durability. Our in-house inspection team utilizes advanced measuring tools and techniques to guarantee precision.

Key Features:

- Dedicated quality control team

- Advanced inspection equipment for accuracy checks

- Strict adherence to quality management systems

4. Spacious & Organized Workshop

Description:

Our spacious workshop is designed for efficiency and safety, enabling smooth operations at every stage of production. Organized workstations, ample space for material handling, and a clean, safe environment are core to our production processes.

Key Features:

- Clean, well-organized workstations

- Ample storage and material handling spaces

- Safety protocols in place to ensure a secure environment